McLaren Automotive revealed the limited edition McLaren Solus GT, with just 25 cars, all are already sold out. The single-seat, closed-cockpit track car was unveiled during Monterey Car Week in California by Michael Leiters, McLaren Automotive Chief Executive Officer.

The McLaren Solus GT in detail

A concept for the virtual world becomes reality

- Originally a virtual concept driven by millions in the Gran Turismo SPORT video game; now a reality as the astonishing McLaren Solus GT

- Striking single, center-seat cockpit and a strong focus on aerodynamic principles throughout

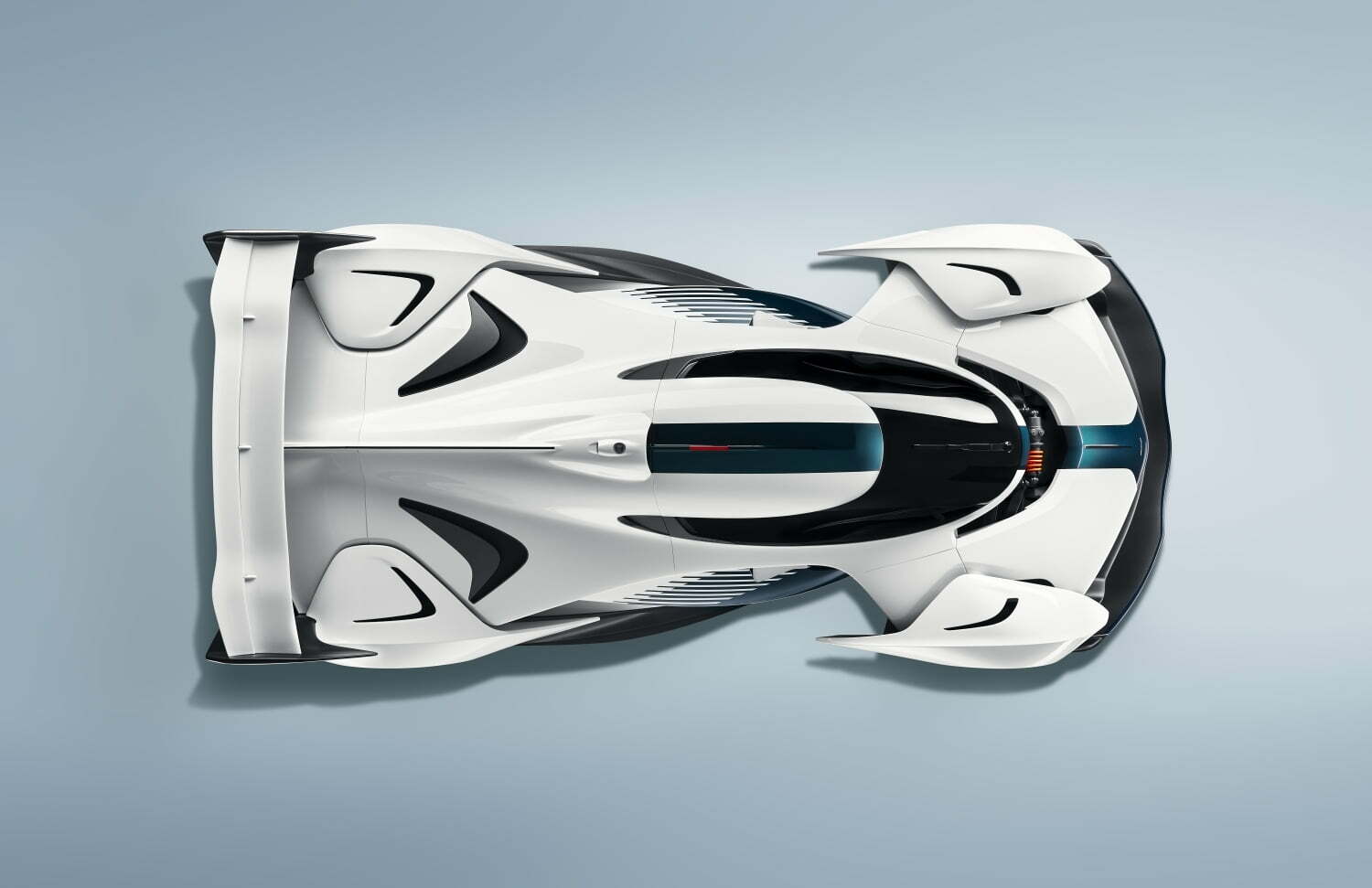

- Showcases McLaren’s signature design features, including ‘hammerhead’ front, teardrop-shaped cabin, and ‘shrink-wrapped’ bodywork

The roots of the McLaren Solus GT are in a stunning concept that is featured in the Gran Turismo SPORT video game.

From the original design sketches through to the virtual gaming triumph and now the astonishing machine that an exclusive few customers will enjoy on track, this is a car that epitomizes the ‘everything for a reason design philosophy and relentless pursuit of engineering excellence within every McLaren. From the outset, the concept was based on proven aerodynamic principles, with a sports-prototype racecar package as its foundation.

The bodywork is very much a technical sculpture, shrink-wrapped over the high-performance engineering package and the two full-length ground effect tunnels. These contain distinctive air intakes at the front and a NACA duct – a low-drag air inlet – which also acts as a step, accelerating the airflow into the radiators.

From the front, the distinctive McLaren ‘hammerhead’ nose helps to separate airflow from the underbody ground effects and the full-length diffuser. The visibility from the wraparound canopy screen of the teardrop cockpit is outstanding, with an uncluttered, 180-degree view of a track. The wheel pods in each corner are not only a dominating design feature, but they also allow overall weight reduction and individually ‘work’ the airflow with a distinctive tear-drop shape that ends in a dramatic blade-like rear edge to calm the turbulent air in the wake of each tire and mitigate pressure build-up within the wheel well.

The rear of the car features a full clam that provides easy access to the engine bay, with super-low trailing bodywork edges that employ the same principles as the Speedtail in order to minimize base pressure across the back of the car, reducing drag.

Engineering a virtual design into extreme reality

- Naturally-aspirated V10 engine chosen to optimize performance, driver engagement and packaging

- Aerodynamic performance integrated into bodywork surfaces to preserve overall shape using CFD and wind-tunnel research

- Heavily optimized structural work includes monocoque geometry

The original engineering brief for the McLaren Solus GT was to turn a prestigious virtual gaming concept into an extremely powerful and highly exclusive McLaren hypercar. This was to be a track-only car, with motorsport engineering expertise and a V10 powertrain coming together to deliver the supreme driver engagement demanded for a no-compromises experience.

The racing-derived engine was chosen for reasons of packaging as well as performance; a pared-down track car with minimal weight and shrink-wrapped bodywork meant having the engine as part of the chassis was a natural choice. This construction technique is rarely seen in production cars for NVH (Noise, Vibration, Harshness) reasons, but in a focused track car it gives many benefits, not least added feedback and exhilarating engagement for the driver.

Once the program parameters were set, the engineering team faced the challenge of integrating real-world aerodynamic performance into the original design surfaces. This was resolved with extensive CFD and wind-tunnel work to prove the aerodynamic, cooling and efficiency properties of the concept.

Racing-inspired chassis design and construction

- Bespoke monocoque structure employs Formula 1 chassis technologies, with front and rear carbon structures

- Low-volume, carbon ‘pre-preg’ process provides strength, rigidity and quality of finish

- Engine and gearbox are stressed chassis members; carbon crash structure is incorporated into the gearbox

- 3D printing techniques used for structural components – titanium halo protection and rollover bar

Like every McLaren built in the last 40 years, the Solus GT features a carbon-fiber monocoque at its heart. However, the single-seat cockpit and production-based engineering processes demanded a bespoke approach embracing the differing disciplines of competition and road car construction and the resulting design takes greater inspiration from motorsport than other McLaren Automotive products, with the monocoque using Formula 1 and sportscar racing chassis technologies. The front and rear impact structures are made from carbon fiber – traditionally McLaren Automotive chassis structures feature aluminum structures fixed to the passenger cell – and with the engine and gearbox both stressed chassis members, there is no requirement for a rear subframe.

The construction of the chassis employs specialist low-volume production methods including a carbon ‘pre-preg’ process whereby the carbon fiber is pre-impregnated with a resin system that simplifies the curing process. The material is ready to lay into the mold before heat and pressure treatment is applied, allowing the higher structural strength demanded by a track-only car. The process also allows a high uniformity of finish to the material that enhances the visual appeal.

The chassis of the Solus GT also features 3D-printed titanium components, including the halo cockpit protection structure and roll hoop. While previously used by McLaren Automotive– notably for the exhaust system of the Elva – this is the first use of the technology for structural components in a McLaren production car and demonstrates the absolute focus applied to finding the best solutions for the Solus GT.

Refined and optimized bodywork and aerodynamics

- Carbon fiber bodywork incorporates aerodynamic surfaces including front splitter, individual wheel pods, structural floor with ground-effect tunnels, and fixed, twin-element, high-downforce rear wing

- Huge downforce generated – at 2,645lbs, greater than the weight of the car – with drag penalty minimized for straight-line speed

- Formula 1-inspired, carbon fiber suspension aero shrouds, air intakes, and sidepod-mounted radiators

Despite the freedom the development team enjoyed in exploring the boundaries of possibilities for the Solus GT as a track car, the exterior design of the virtual reality concept did impose restrictions on what could be done if the real car was to retain the ‘wow’ factor of the car that featured in Gran Turismo SPORT.

As befits an ultra-lightweight track-only car, the bodywork of Solus GT is made from carbon fiber; the complex shapes and swooping lines are achieved without the weight penalties that would come from the use of conventional metal panels. The form of these has been finely honed – ironically in virtual reality – to ensure stability and maximize aerodynamic efficiency for both straight line-speed and downforce.

A large front splitter feeds air into ground-effect tunnels in the full structural floor, which has been designed to accept high aerodynamic loads. The air exits the car via a full diffuser. The front wheels are outboard of the main bodywork, with the suspension wishbones exposed to the airflow and shrouded in aerodynamically-shaped carbon fiber that directs air towards the sidepod-mounted radiators. The sidepod-siting of the high-temperature radiators is directly inspired by motorsport, providing a direct cooling solution for engine fluids and reducing frontal surface area.

A motorsport-inspired air intake above the cockpit, which is integrated into the design of the roll hoop cover, takes in cold and flow-conditioned air above the car while also creating a pleasingly engaging engine induction sound.

The twin-element, the fixed rear wing is one of the more distinctive visual features of Solus GT. Designed to maximize downforce over the rear of the car, it works alongside the combination of high-downforce ground effect and low pitch sensitivity from the motorsport-derived suspension system, to negate the need for active front or rear wings and so help to keep weight down.

Overall, the aerodynamic package downforce exceeds the total weight of the car, but the downforce to drag ratio is also optimized, aiding straight-line performance and enhancing cornering speeds.

Unique, single central seat interior

- The driver enters car via a sliding canopy incorporating a Formula 1-style halo cockpit protection device

- Single-seat cockpit with fixed seat and adjustable pedals

- Main driver controls and TFT instrument display mounted on carbon-fiber-structured steering wheel

- Rear wide-angle camera located above roll-hoop, linked to driver view screen

The Solus GT McLaren driving experience begins even before the V10 engine is started – simply stepping into the cockpit is an event in itself. Instead of signature McLaren dihedral doors, a sliding canopy – more akin to that of a fighter jet – is opened using a mechanical lever. The spring-loaded canopy moves through a shallow arc, lifting clear of the cockpit and sliding forwards to allow easy access to the driving seat.

Recent technological safety innovations from the top tiers of motorsport are integrated into the design, with the canopy reinforced by a halo-style structure to protect the driver. An escape hatch is also built into the canopy to allow safe departure from the cockpit should the sliding mechanism be obstructed.

The interior is purpose-built for extreme track performance; an owner can specify their car with an entirely bespoke environment, but it will remain focused on the driving experience. The molded seat is fitted with a 6-point harness and is fixed in position; instead, the pedal box is adjustable as in a race car, but with the convenience of being able to be operated from a sitting position.

To ensure the single seat is a perfect fit for the customer, MSO has adopted a process taken from motorsport which is yet another example of the full range of McLaren expertise being available for the Solus GT. A phenolic resin-based system with advanced micro-bead technology is used to create a mold from which the seat is created, ensuring in turn that the driver remains comfortable in the car throughout the most intense track driving sessions.

Almost all controls are concentrated on the steering wheel, which is constructed from carbon fiber. Inspired directly by motorsport, all essential functions are easily reached with both hands on the wheel. A full HVAC air system also keeps the driver fully alert throughout the driving experience.

Above the driver’s head are switches for vehicle ignition and the fully plumbed-in emergency fire extinguisher. This area also houses the rear-view display, streamed in real-time from a camera located on the roll hoop behind the driver’s head. The wide-angle camera provides a comprehensive rear view of the track to allow traffic to pass on a slowing-down lap or aid pit-lane maneuvering.

Powertrain with a proven motorsport pedigree

- Motorsport-derived, naturally-aspirated 5.2-liter V10 engine that revs to over 10,000rpm

- McLaren-specific engine, with crank, cylinder capacity, air intake, and exhaust system all bespoke to Solus GT

- Gear-driven camshaft and ancillary systems, with no chains or belts in the engine

- Barrel throttles for individual cylinders sharpen throttle response

The 5.2-liter V10 engine specified to power the McLaren Solus GT is incorporated into the vehicle chassis structure. The engine capacity is unique to the Solus GT, as are the air intake and exhaust system. The induction system directs air towards barrel throttles that are individual to each cylinder – a technology that is not suitable for road use but offers clear advantages in engine performance, including improved throttle response.

The engine also incorporates low-volume machined components optimized for performance and is entirely gear-driven; there are no chains or belts for ancillary systems. Output is greater than 829bhp, with the full benefit of the ram effect provided by the high air intake and the engine revving past 10,000rpm. Maximum torque is more than 479lb-ft.

The resulting performance is a target acceleration time of 2.5 seconds from standstill to 62mph and a maximum speed over 200mph, despite the Solus GT generating downforce that exceeds its weight.

Competition gearbox

- Seven-speed sequential gearbox

- Incorporates bespoke casting and aluminum casing with magnesium panels; rear suspension locates to gearbox

- Uses motorsport-derived straight-cut gears

- Carbon fiber clutch with automated software control for a combination of both aggressive shift strategy and user-friendly operation

The Solus GT has a seven-speed sequential gearbox, with race-proven internals located within a bespoke casting and casing, designed as a mounting point for the rear suspension. The casing is made from aluminum, with magnesium panels optimizing weight.

Originally designed for LMP sportscar applications, the gearbox internals include straight-cut gears, a technology not usually incorporated in production cars for reasons of NVH refinement but acknowledged as providing greater efficiency than helical-cut gears in a high-performance track car.

The gearbox is engaged by a carbon fiber clutch, designed to complement aggressive gearshift strategy demanded in a track application. It is though also fully automated and controlled by software – removing the need for a pedal or lever-operated clutch control – to aid the driver when pulling away from the pit-lane.

Track-focused suspension design

- Formula 1-inspired suspension design incorporates double wishbones and front pushrod and rear pullrod activated torsion bars

- Manually adjustable four-way dampers

- Incorporates anti-roll bars, ride-height springs and a heave spring and damper system

The McLaren Solus GT was designed from the outset as a track-only car and its suspension follows the principles of motorsport engineering, starting with the wheels located via double wishbones. With the front wheels mounted outboard of the main body, the front damping is inboard with pushrods operating torsion bars and corner dampers. At the rear, the bars are linked to pullrods, and the rear suspension is mounted to the gearbox casing.

The wishbones and rods are fabricated from steel for enhanced durability, but the front suspension links are encased in carbon fiber shrouds for aerodynamic efficiency. The system also incorporates ride height springs and a heave spring and damper system. This is employed to provide stiffness at speed by limiting vertical movement, the effect of this is to create a more aerodynamically stable profile, making the car’s dynamic behavior at speed more predictable and therefore increasing driver confidence on high-speed tracks.

Housed within the distinctive wheel pods are 18-inch forged aluminum wheels with center locking nuts, shod with Le Mans Prototype-specification tires available in both slick and wet compounds. Braking is provided by 6-piston monobloc machined aluminum calipers with carbon brake discs and pads. Bias between the front and rear brakes can be adjusted by the driver in the cockpit.

Each axle is linked by anti-roll bars, which are connected via drop links. Both bars are adjustable.

Discover more from SNAP TASTE

Subscribe to get the latest posts sent to your email.